An Introduction to Fusion Deposition Modeling ABS Plastic

A guide for manufacturing professionals new to 3D printing.

First published May 24, 2023

Last updated June 14, 2023

Overview

The expiration of key patents in 2009 led the way for the development of additive manufacturing as an industry and hobby. This explosive growth continues with new materials and new methods of 3D printing them. Concrete, titanium, chocolate, and glass are regularly 3D printed, but FDM machines that model thermoplastic filament remain the most common. Stores sell a basic FDM printer for $100USD1, while many commercial FDM printers list for $10,000 or more.

The intended audience of this article are individuals 1) in manufacturing or adjacent industries, 2) who have seen FDM 3D prints and perhaps can identify a 3D printer, but 3) have minimal or no hands-on experience operating one.

The topic of this article is a specific 3D-printable plastic, acrylonitrile butadiene styrene (ABS):

- The material properties that make it attractive,

- What printing ABS requires, and

- A comparison with other 3D-printable thermoplastics.

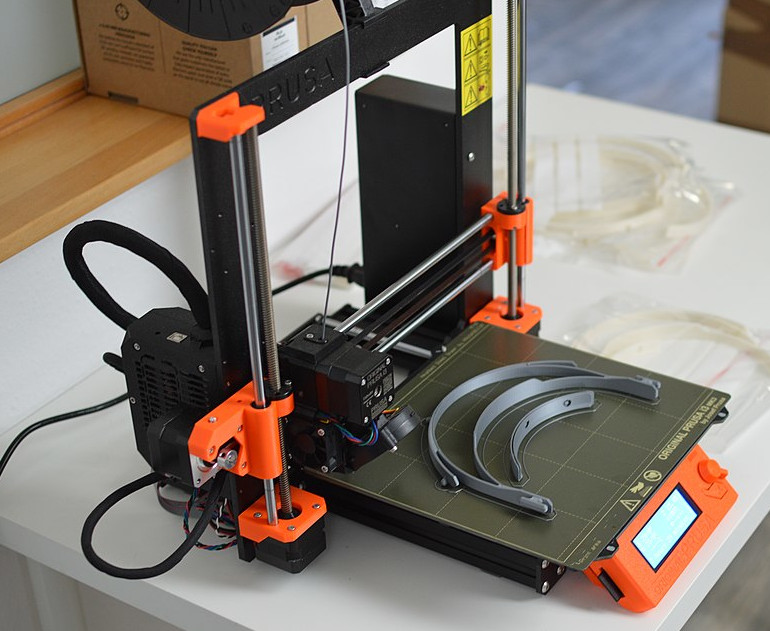

An FDM 3D printer, manufactured by Prusa.

Source: European Space Agency

Table of Contents

-

Specifically, the Creality Ender 3 Pro lists for around $100USD. Higher quality entry-level machines can be found for $250-$300. ↩