The OmniBox Story

The Requirements

Hardware

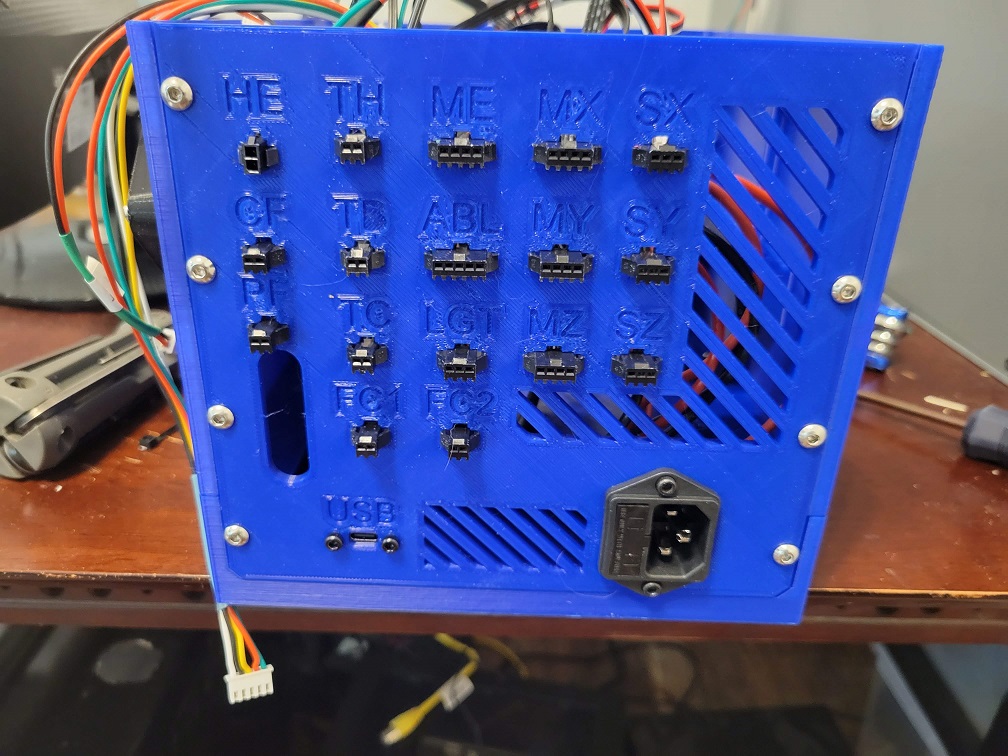

Enclosed 3D printers require more hardware than a basic 3D printer:

- Lighting

- Webcam(s)

- Enclosure thermistor

- Exhaust fan (temperature-controlled)

- Filtration fan(s)

Isolation From Heat

Most electronics will overheat in the 50C (120F) or higher air temperatures common in enclosures. The developer printed his first of Steve Burcham's cases to remove electronics from such heat; OmniBox is derived from his work.

Room for Growth

3D printers have electronics cases generally no larger than they need to be; this makes expansion difficult (or impossible without a second electronics case).

OmniBox instead encloses all of your electronics in one place.

Flexibility and Accessibility

The developer (as of this writing) has assembled over 25 OmniBoxes, with at least two for each release. The case is designed to put the most frequently accessed components within immediate reach and minimize wasted effort.

Zip tie anchors are positioned throughout the case to aid organization and keep it neat.

Ample Room

The release of MCUs with 8 stepper sockets increased the possible size of MCU boards. The MCU tray mount has plenty of clearance on all sides to allow for oversized boards like the BIGTREETECH Manta M8P to fit without feeling cramped.

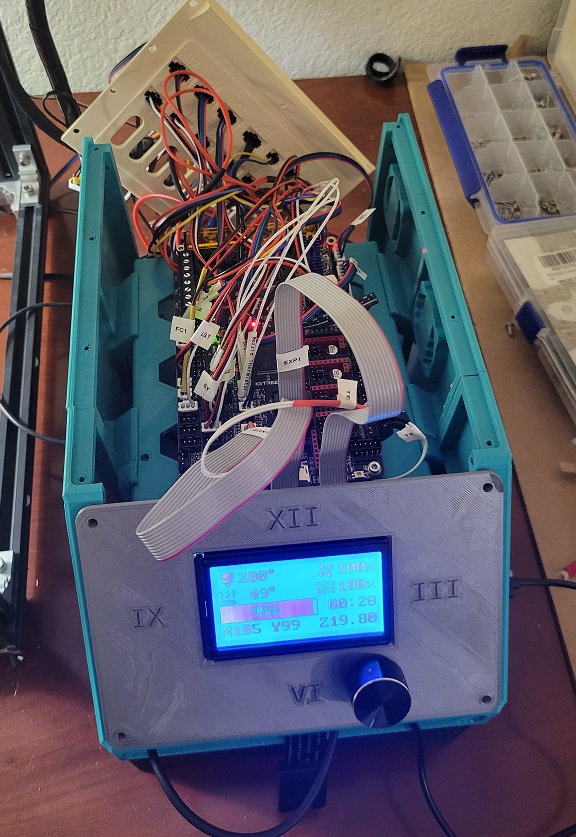

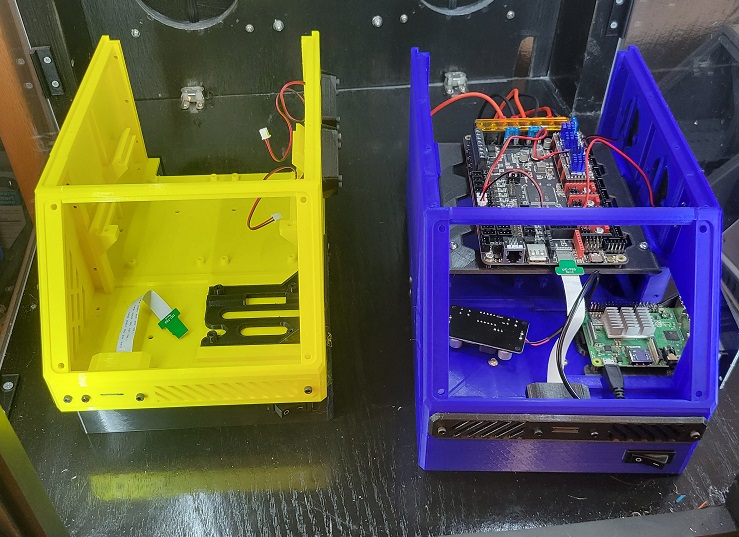

Early Development Gallery

These photos detail some of the evolution of Steve's original case into OmniBox.